Catalog

產品介紹

CW-7000 Series Combiner Workstation

CW-7001, for N x1, (N+1) x1 end pump combiner, up to 37×1 or (36+1) x1

High power fiber optic systems are constantly evolving and so are their internal optical components. The Lightel CW-7000 series workstation is a very useful tool to aid in the development and manufacturing of fiber bundle tapering and fiber laser pump combiner manufacturing. Ideal for production or R&D, the CW-7000 is customized for End-Pump Combiner fabrication.

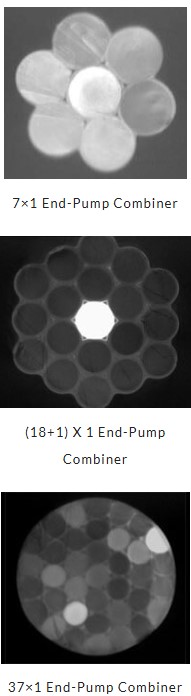

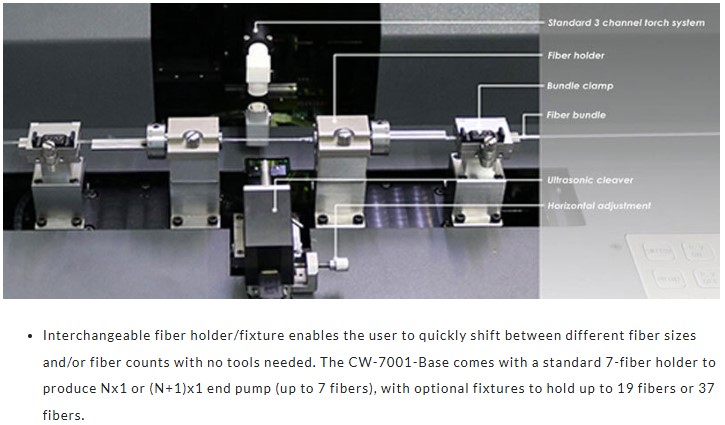

The CW-7000 series combiner workstation was designed based on Lightel’s decades of practice in fiber fusion technology and hands-on experience in manufacturing fiber optic pump combiners. With our specially simplified fiber loading and holding fixtures, there is no need to use or taper any type of glass tubes or capillaries. The fabrication process is simple and easy to learn. Also, the fiber holder/fixtures are virtually maintenance-free and extremely easy to exchange for different fiber sizes and fiber counts.

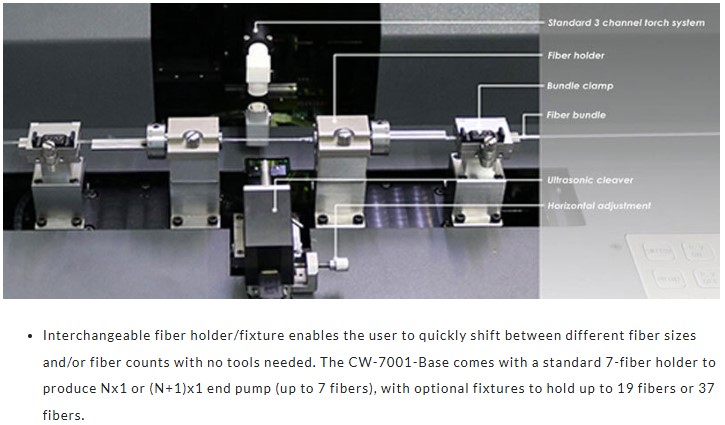

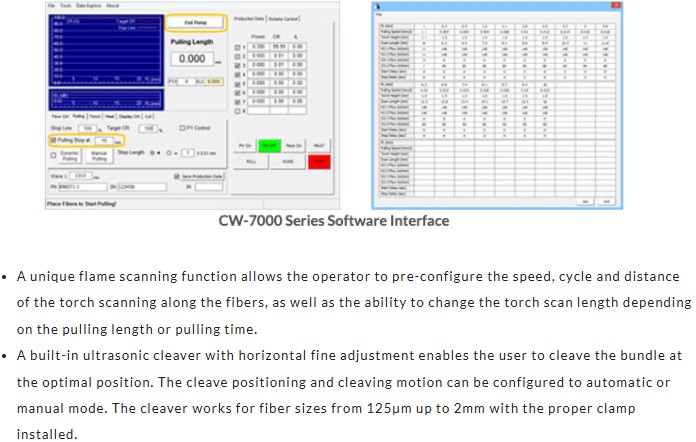

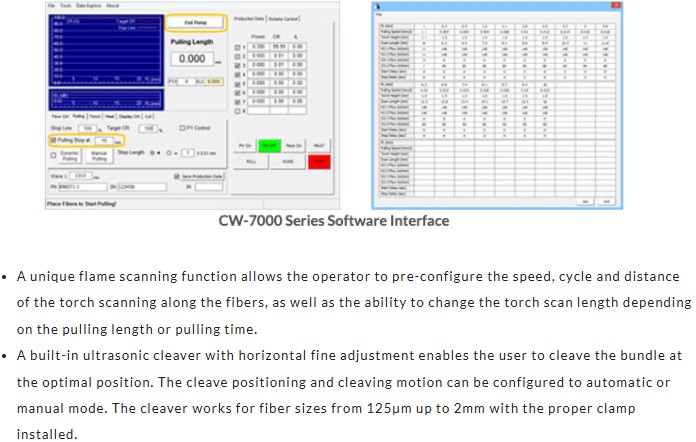

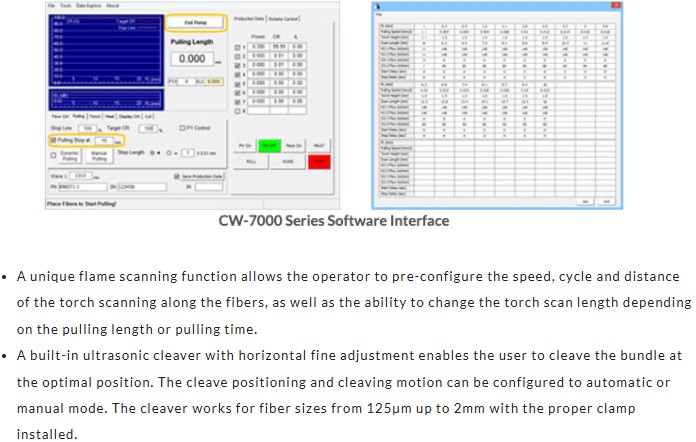

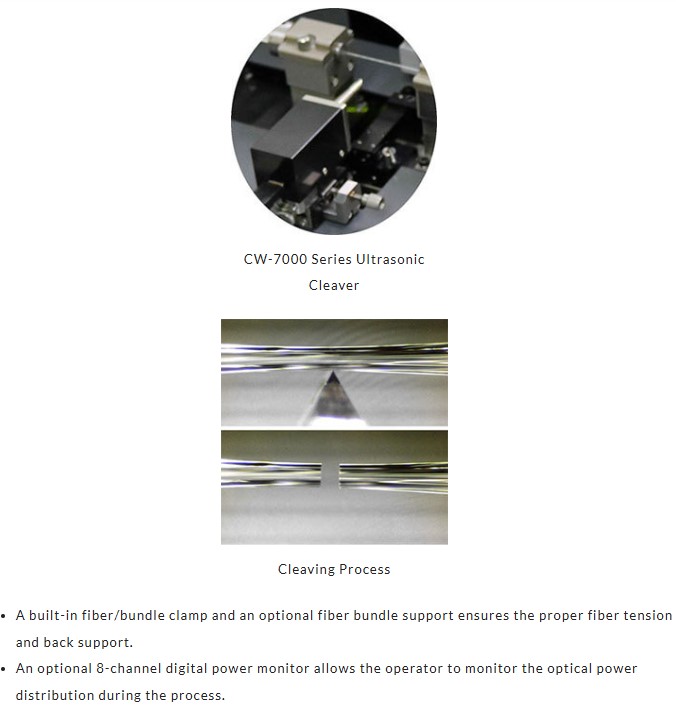

Comprehensive software features include highly configurable dynamic pulling, torch scanning, gas flow control and cleaver positioning. These features allow the user to control most parameters and customize their own recipe, making the workstation ideal for both production and research.

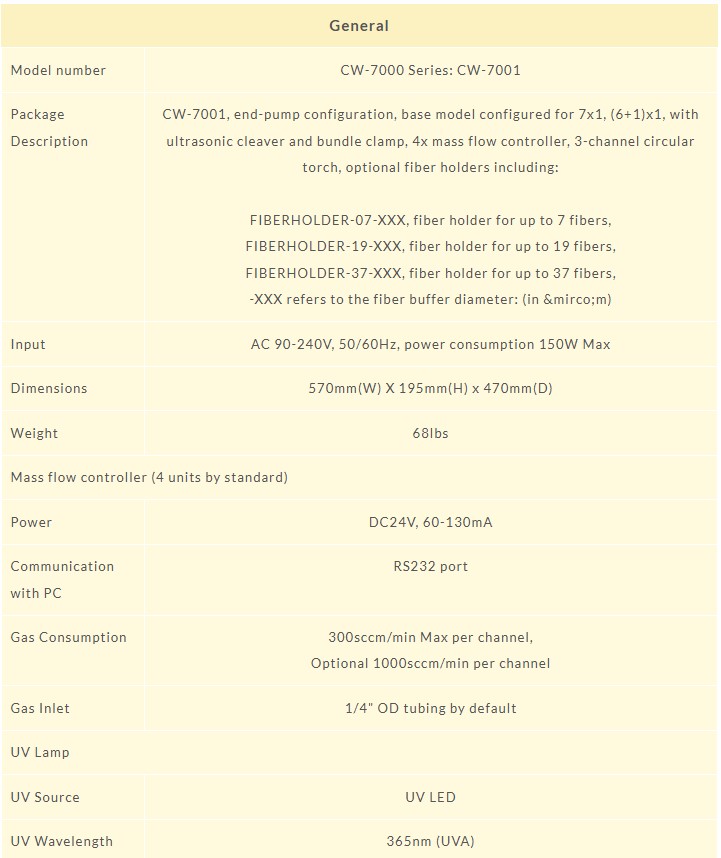

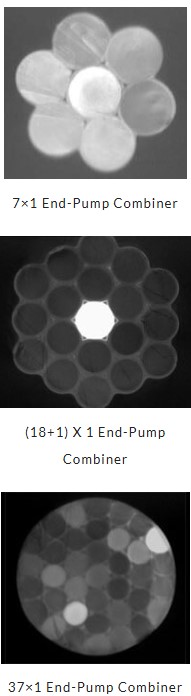

Cross-section Images

Key Features

Simple fixture design allows the fiber to be easily loaded. No glass tubes or capillaries are required.

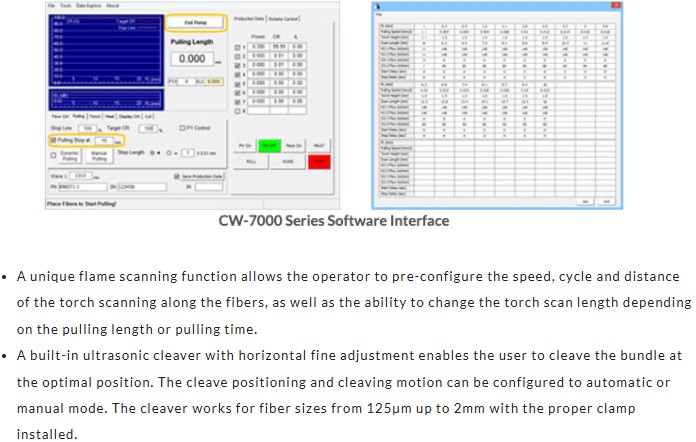

Specifications

High power fiber optic systems are constantly evolving and so are their internal optical components. The Lightel CW-7000 series workstation is a very useful tool to aid in the development and manufacturing of fiber bundle tapering and fiber laser pump combiner manufacturing. Ideal for production or R&D, the CW-7000 is customized for End-Pump Combiner fabrication.

The CW-7000 series combiner workstation was designed based on Lightel’s decades of practice in fiber fusion technology and hands-on experience in manufacturing fiber optic pump combiners. With our specially simplified fiber loading and holding fixtures, there is no need to use or taper any type of glass tubes or capillaries. The fabrication process is simple and easy to learn. Also, the fiber holder/fixtures are virtually maintenance-free and extremely easy to exchange for different fiber sizes and fiber counts.

Comprehensive software features include highly configurable dynamic pulling, torch scanning, gas flow control and cleaver positioning. These features allow the user to control most parameters and customize their own recipe, making the workstation ideal for both production and research.

Cross-section Images

Key Features

Simple fixture design allows the fiber to be easily loaded. No glass tubes or capillaries are required.

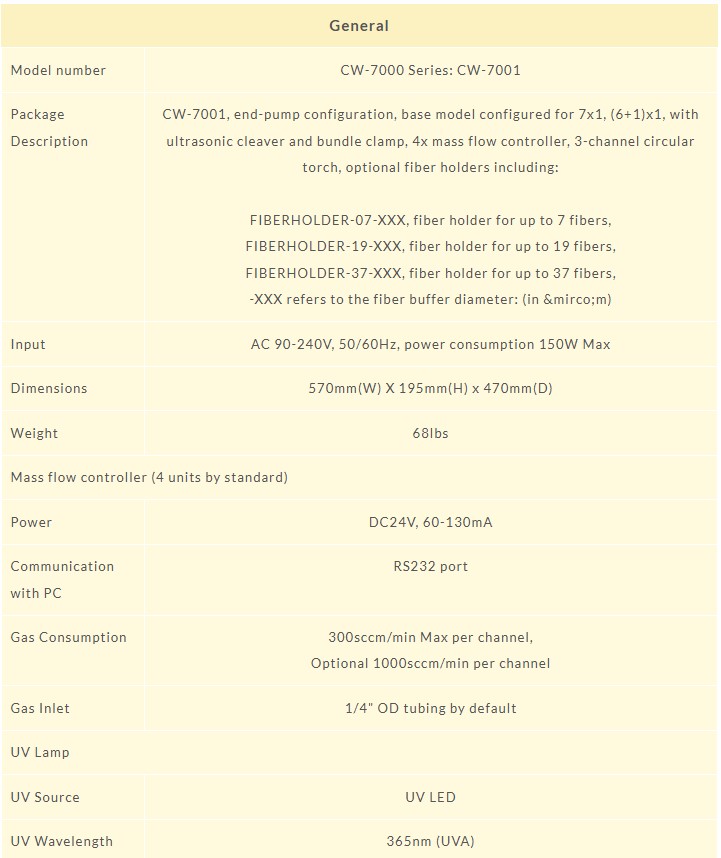

Specifications